Safety knowledge about common risk factors of power connectors

Oct 05, 2023

When it comes to consumer electronics, there are few other products as basic and commonly used as power connectors. Plugs and sockets of all kinds are very important necessities in life, providing electrical current channels for various products to be connected to the SEDlicable main power supply.

A power connector refers to the part that plugs into a wall socket, or socket. They come in an astonishing number of types, shapes, and sizes, and have varying voltage capacities depending on the power supply function or need. Their designs can also vary greatly depending on national standards, as anyone who has traveled abroad and wanted to charge their smartphone can attest.

However, even though there are so many types, the risk of high-risk accidents is the same in all of them. And because power connectors are so commonly used, it's important to understand their dangers and malfunctions today.

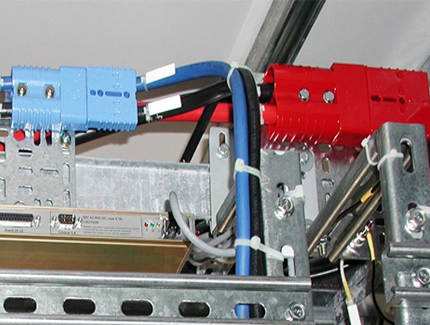

Type of power connector (such as:battery terminal connector plug,forklift battery charger connector,power transmission connector).

Power connectors can be divided into two types: alternating current (AC) or direct current (DC). When considering the risks associated with power connectors, it is important to understand how the two types of connectors are similar and different.

AC power connector) is more common, and you can see a variety of these connectors in your home or office every day. AC power plugs and receptacles connect electronics to a building's alternating current (AC) lines, and their host transformers, which regulate voltage and carry current across multiple points. In other words, AC connectors can work in a wider range and at more levels.

DC type connector, unlike its cousin AC system, DC has no loop cycle. On the contrary, the DC connector works in one direction, and its current flows through the circuit in one direction. You'll find this type of electrical current system mostly found in batteries and generators, where the electrical current is typically generated by an internal fuel cell.

Common risk factors

Although the SEDearance and design of modern products have greatly reduced the chances of people coming into direct contact with live currents, suffering electric shocks, or causing fires due to circuit problems, there are still many accidents related to power connectors.

Extension cord. Facts have proved that sometimes useful things are not necessarily good things. Those power strips that are connected through a plug, allowing you to charge more electronic devices more conveniently, not only bring convenience to you, but also bring more safety risks. Overloading AC current in extension cords is well known and can cause problems such as system overheating, voltage surges, external sparks, and even possible fire hazards. Always check extension cords for signs of cracked plastic insulation, and be wary of plugging everything into the same power strip and turning it on at the same time.

water. Since water is a very good conductor of electricity, the power connector must be kept as far away from water as possible. In most situations, such as in a bathroom, even the slightest touch of an electrical device with wet hands can cause an electric shock. A well-designed layout will install power sockets as far away from sinks and shower trays as possible. Everyone must be careful when using electrical equipment near water sources.

Uninsulated wire. Improper insulation of electrical wires can be a common problem during building construction or remodeling. This is also one of the most dangerous problems, so there are many existing laws and regulations that have been established to reduce the exposure of circuit systems. In addition, circuits in some old buildings may have been insulated before but have aged and worn over time, so they must be inspected frequently. Double insulation is also required for some ungrounded equipment or buildings with large power consumption. Not uncommon.

Read More

network supported

network supported