Safe and efficient: in-depth analysis of the design and specifications of heavy-duty truck automotive wiring harnesses

Dec 26, 2023

Automotive wiring harness, as the network main body of automotive circuits, its design and assembly process is crucial. This article provides an in-depth introduction to the design requirements and specifications of heavy-duty truck automotive wiring harnesses, and also discusses common problems and improvement plans during the assembly process.

**1.1 Wiring Harness Design Process**

The design principles of automotive wiring harnesses are to pursue the shortest wire distance, the minimum number of wires, the most SEDropriate wire cross-section, and the selection of SEDropriate connectors and terminals to ensure correct and reliable connections, thereby improving work reliability. The complete process of wiring harness design for level 6 projects includes electrical function table design, fuse and relay configuration, schematic design, three-dimensional wiring harness and power distribution device layout, generation of two-dimensional wiring harness diagrams, generation of wiring harness and power distribution device installation diagrams, and wiring harness system details. Generation, wire harness assembly verification, electrical system functional verification.

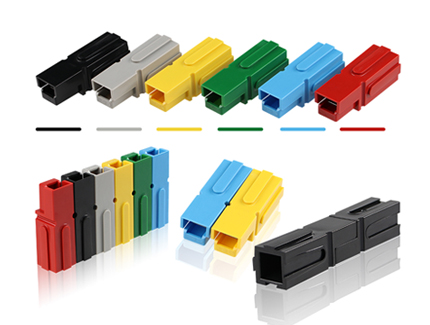

Lithium battery battery extension cord plug

1.2 Subsystems and components included in design specifications

The design specifications cover multiple systems and components, including 370 electrical schematics, 374 body wiring harness, and 362 chassis wiring harness. Chassis wire harness covers frame wire harness 1, frame wire harness 2, engine wire harness, transmission wire harness, flip mechanism wire harness, starter power wire, battery wire, ground wire, etc.; body wire harness includes body main wire harness, ceiling wire harness, left door wire harness, etc. Wiring harness, right door wiring harness, etc.

EC5-F/M car emergency start power cord

**2.1 ETX vehicle wiring harness classification**

ETX vehicle wiring harness is divided into body part and chassis part. The body part includes the main body wiring harness assembly, cab ceiling wiring harness assembly and left/right door wiring harness assembly (with electric door windows). The chassis part includes the front frame wire harness assembly, the rear frame wire harness assembly, the engine pre-installed wire harness (non-National IV models), the flip mechanism wire harness, the transmission wire harness and the power cable (battery to frame).

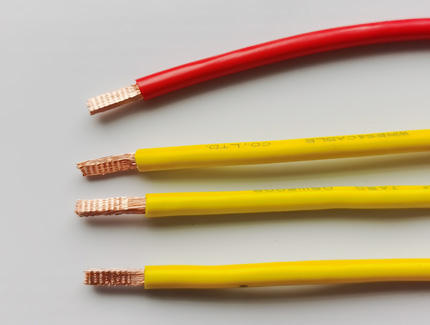

Single pole 45A plug double spliced soft silicone cable

**2.2 Optional parts**

The vehicle also involves some optional assemblies, such as brake wire harness assembly, ABS wire harness (inside the cab) and disc bridge wire harness assembly. The brake wiring harness assembly includes the solenoid valve and wheel speed sensor, the ABS wiring harness includes the ECU and ABS switch, and the disc bridge wiring harness assembly includes the friction plate switch.

Through detailed design and specifications, the efficiency, reliability and safety of automotive wiring harnesses are ensured.

Read More

network supported

network supported