The Anatomy of Electric Forklift Connectors

Oct 14, 2023

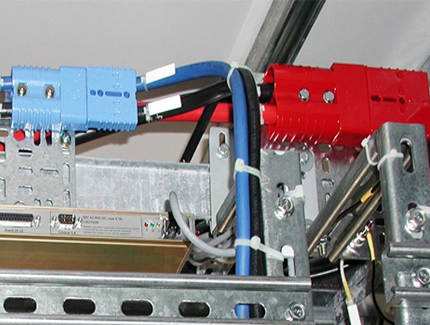

As the overseas market continues to expand and the effects of global economic globalization take center stage, an increasing number of countries are shifting their manufacturing industries to China. Industry experts predict that as foreign enterprises continue their migration to China and Chinese electric forklift connector companies intensify their research and development efforts, bolstering technological advancements, China will play a pivotal role in the production of automotive connectors in the coming years. With this shift, the expectations for automotive connectors are set to rise. Electric forklift connectors primarily comprise four key components.

**1. Insulator:**

The insulator, also known as the electric forklift connector base or insert, serves the purpose of arranging contact elements in their desired positions and spacings. It ensures insulation between contact elements and between contact elements and the outer shell. Key requirements for insulating materials include high insulation resistance, voltage resistance, and ease of processing.

**2. Contact Elements:**

Contact elements represent the core components that enable the electric forklift connector to fulfill its electrical connection function. Typically, they consist of male plug contact elements and female socket contact elements, forming contact pairs that complete the electrical connection through male-female engagement.

**3. Housing:**

Also referred to as the outer shell, the housing encases the electric forklift connector, providing mechanical protection for the internal insulating board and pins. It facilitates the alignment of plugs and sockets during engagement, securing the connector to the equipment.

**4. Accessories:**

Accessories are divided into structural and mounting components. Structural accessories include items such as retaining rings, positioning keys, locating pins, guide pins, connecting rings, cable clamps, sealing rings, and sealing gaskets, among others. Mounting accessories consist of screws, nuts, bolts, spring rings, and more. These accessories often include standard and universal components.

Electric forklift connectors serve as the vital bridge in forklift systems. Their stable and orderly operation hinges on the perfect coordination of these four structural components. Recognizing the significance of electric forklift connectors, customers must be meticulous when selecting the connector's components, ensuring that a single component's failure does not result in the entire vehicle system's collapse. Indeed, the quality of components ultimately shapes a superior electric forklift connector, ensuring the safe and orderly operation of forklift systems.

**Recommended Electric Forklift Connectors:**

- **REMA DIN Connector 80A**

- **REMA DIN Connector 160A**

- **REMA DIN Connector 320A**

These connectors find widespread use in forklifts.

If you are in search of other connectors, we also offer SED plugs, battery connectors, UPS power connectors, dual-pole connectors, single-pole connectors, connector accessories, and SED connector OEM wiring harness processing services.

In the intricate world of electric forklift connectors, the future is bright, and China stands at the forefront of innovation and production.

For your next project, consider the quality and reliability of REMA DIN connectors.

Read More

network supported

network supported